In India’s rapidly expanding industrial landscape, conveyor systems have become the backbone of efficient material handling. From mining and cement plants to power stations, ports, warehouses, and manufacturing units, conveyors ensure uninterrupted movement of bulk materials and goods. At the heart of every reliable conveyor system are idler rollers and conveyor rollers—components that may appear simple but directly influence system performance, belt life, and operating costs.

This is where Albatross, a leading Conveyor Idler & Roller Manufacturer in India, plays a critical role. With a strong focus on engineering precision, durability, and application-specific design, Albatross has established itself as one of the most dependable names in the conveyor component industry.

The Role of Idler Rollers in Conveyor Systems

Before choosing a manufacturer, it is important to understand why idler rollers are so essential.

What is the idler roller?

An idler roller is a non-powered cylindrical roller used to support and guide the conveyor belt. Unlike drive rollers, idlers do not move the belt; instead, they reduce friction, maintain belt alignment, and support the load.

What is an idler used for?

Idlers are used to:

- Support the conveyor belt and material load

- Prevent belt sagging

- Improve belt tracking

- Reduce wear and tear on the belt

- Enhance overall conveyor efficiency

A high-quality idler roller directly translates into lower maintenance costs and longer belt life.

Albatross – A Trusted Conveyor Idler & Roller Manufacturer in India

As a reputed Conveyor Idler & Roller Manufacturer in India, Albatross combines technical expertise with modern manufacturing infrastructure. The company designs and manufactures idler rollers that perform consistently under demanding industrial conditions.

Albatross focuses on delivering rollers that are:

- Structurally strong

- Dimensionally accurate

- Smooth in rotation

- Resistant to wear, dust, and moisture

This commitment has positioned Albatross among the top idler roller manufacturers in India.

Why Albatross Is Among the Best Idler Roller Manufacturers in India

India has a wide range of conveyor component suppliers, but only a few truly qualify as the best idler roller manufacturers in India. Albatross stands out due to the following strengths:

1. Engineering-Driven Manufacturing

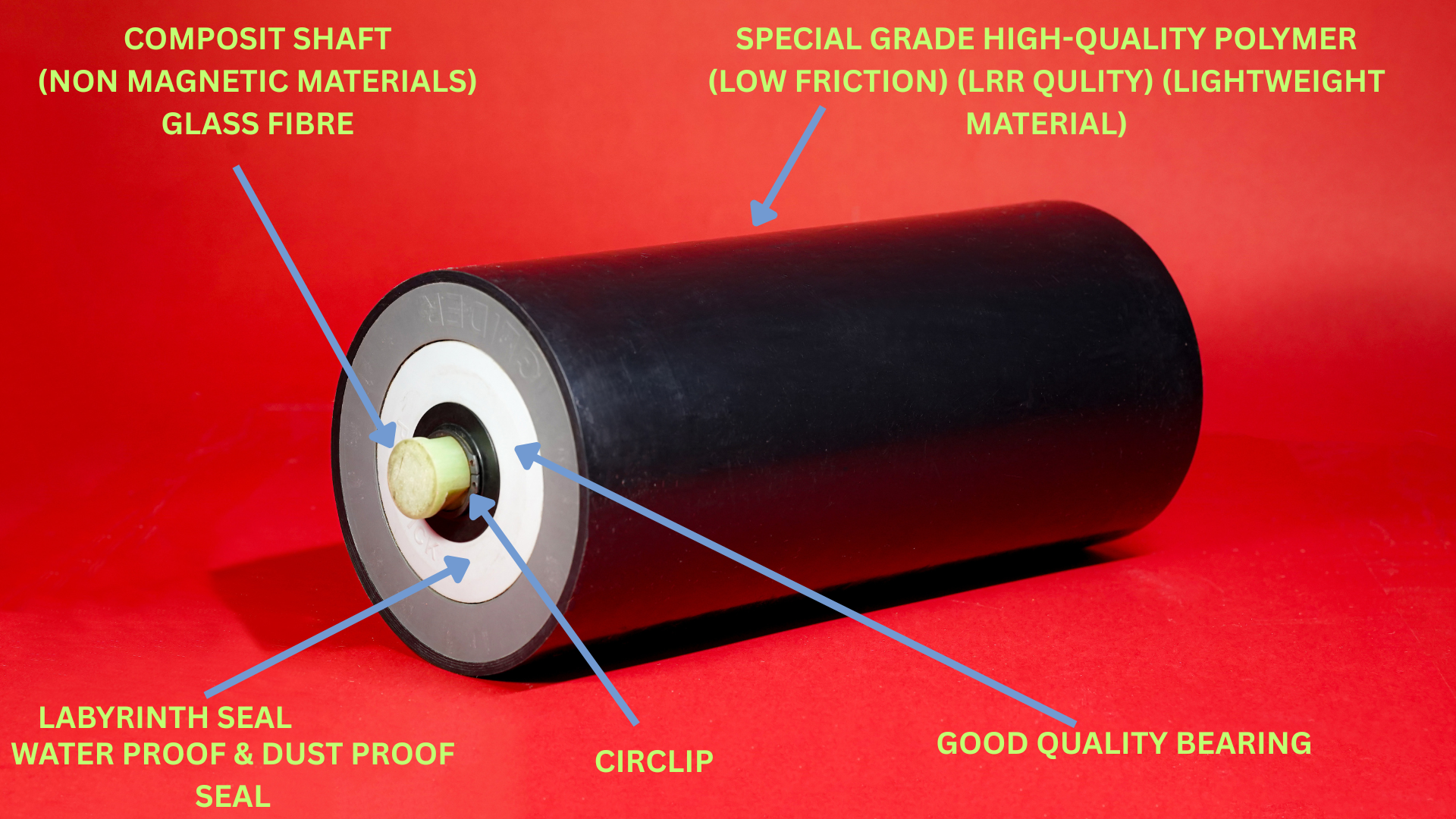

Each idler roller is manufactured using carefully selected raw materials, precision machining, and controlled assembly processes to ensure consistent performance.

2. Wide Industrial Application

Albatross idler rollers are used across multiple industries, including:

- Mining and mineral processing

- Cement and clinker handling

- Thermal and renewable power plants

- Steel and metal industries

- Ports and bulk terminals

- Warehousing and logistics

3. Proven Heavy-Duty Performance

As one of the leading heavy duty idler roller manufacturers in India, Albatross designs rollers capable of handling high loads, abrasive materials, and continuous operations.

4. Customization Capability

Different conveyor systems demand different specifications. Albatross offers customization in:

- Roller diameter and length

- Shaft size and material

- Bearing configuration

- Sealing arrangements

- Application-specific designs

Industrial Idler Roller Manufacturer in India for Reliable Conveyor Systems

Industrial conveyor systems operate in environments where dust, heat, moisture, and heavy loads are common. As an experienced industrial idler roller manufacturer in India, Albatross focuses on reliability and longevity.

Their rollers are designed to:

- Reduce rolling resistance

- Minimize vibration and noise

- Improve belt tracking

- Operate smoothly over long periods

This makes them suitable for both standard and high-capacity conveyor installations.

Idler Roller Conveyor Applications

An idler roller conveyor depends entirely on the quality and alignment of its rollers. Poor-quality idlers can lead to belt misalignment, increased power consumption, and frequent breakdowns.

Albatross idler rollers help conveyor systems achieve:

- Smooth belt movement

- Reduced energy loss

- Lower maintenance downtime

- Consistent material flow

These benefits are especially critical in continuous-operation industries such as mining and cement.

Common Idler Roller Types Manufactured by Albatross

Understanding idler roller types is essential for selecting the right solution. Albatross manufactures a comprehensive range, including:

Carrying Idlers

Support the loaded side of the conveyor belt.

Return Idlers

Support the empty return side of the belt.

Impact Idlers

Used at loading points to absorb shock from falling materials.

Troughing Idlers

Shape the belt into a trough to carry bulk material efficiently.

Training Idlers

Help maintain proper belt alignment and prevent belt wandering.

Each type is manufactured to meet specific operational requirements.

Heavy Duty Idler Roller Manufacturers in India – Built for Harsh Conditions

In sectors like mining, cement, and power generation, conveyor components must withstand extreme conditions. Albatross, recognized among heavy duty idler roller manufacturers in India, focuses on:

- Thick, high-strength roller shells

- Premium-grade bearings

- Effective dust- and moisture-proof seals

- Long service life with minimal maintenance

These features significantly reduce total operating costs.

What Is the Price of Idler Roller?

The price of an idler roller varies based on:

- Roller size and type

- Material specifications

- Bearing quality

- Application and load capacity

Standard idlers are generally economical, while heavy-duty or customized rollers are priced higher due to enhanced durability and performance requirements.

Difference Between Drive Roller and Idler Roller

A common question in conveyor systems is the distinction between these two components.

- Drive Roller: Powered component that moves the conveyor belt

- Idler Roller: Non-powered component that supports and guides the belt

Both are essential, but they perform entirely different functions within the system.

Serving Customers Across India

While Albatross has a strong manufacturing presence, it serves clients across the country. Whether you are looking for a supplier in Bengaluru, eastern India, or searching for an Idler Roller Manufacturer in Kolkata, Albatross supports pan-India requirements with consistent quality and timely delivery.

Conclusion

Idler rollers are critical to conveyor efficiency, safety, and cost control. Selecting the right manufacturer ensures smooth operations and long-term reliability. As a trusted Conveyor Idler & Roller Manufacturer in India, Albatross continues to support diverse industries with robust, precision-engineered idler roller solutions.

For businesses seeking the best idler roller manufacturers in India, industrial idler roller manufacturers in India, or heavy duty idler roller manufacturers in India, Albatross remains a dependable partner for performance-driven conveyor systems.